DanPerryy

Well-Known Member

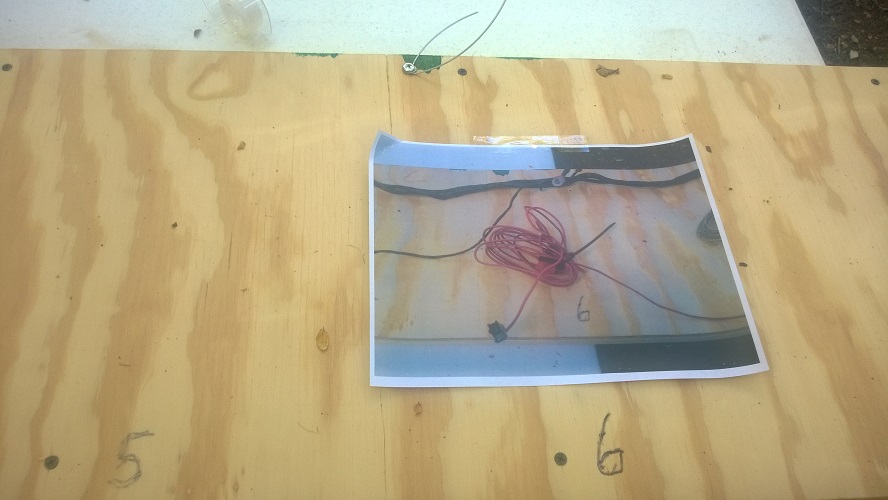

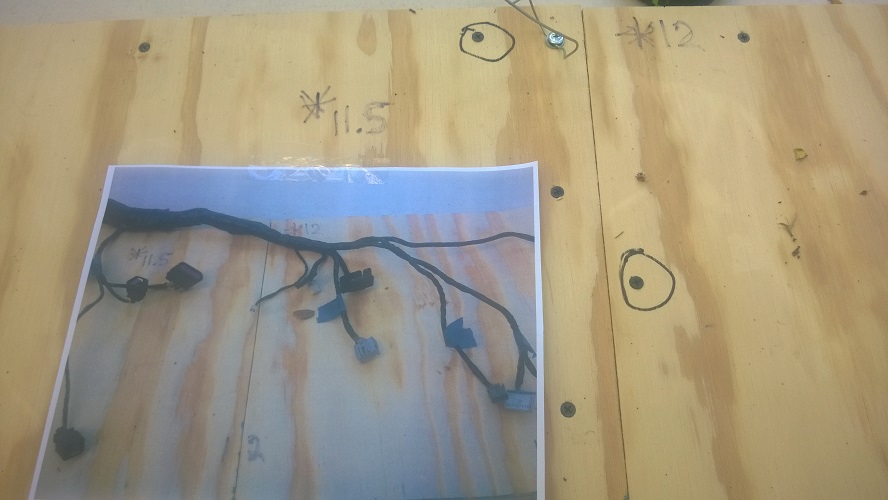

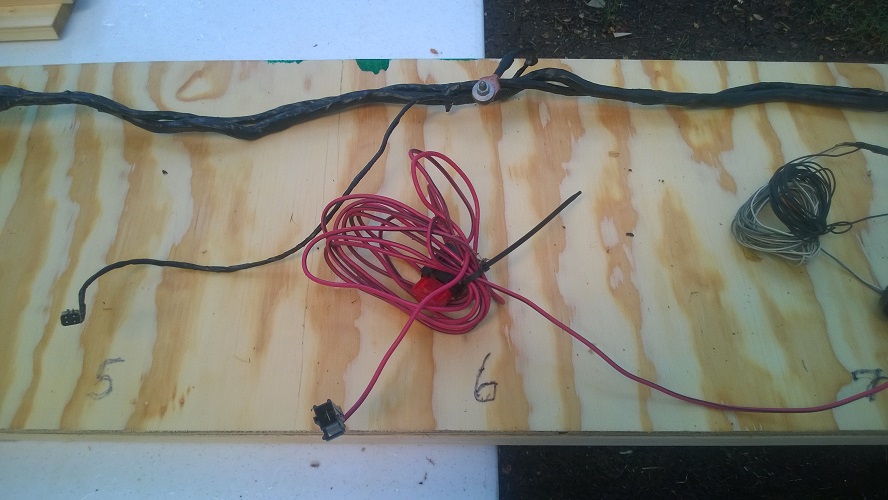

This afternoon - started on the main harness. I built a long table - 16' and marked it each foot. I then laid Lonny's and Adam's lender main harness on the table and took pictures of the finished main harness (see attached). I printed the pictures and taped them to the table at their proper position.

I attached some holding ties (a piece of bailing wire screwed down to the table) at positions along the completed harness.

I attached some holding ties (a piece of bailing wire screwed down to the table) at positions along the completed harness.

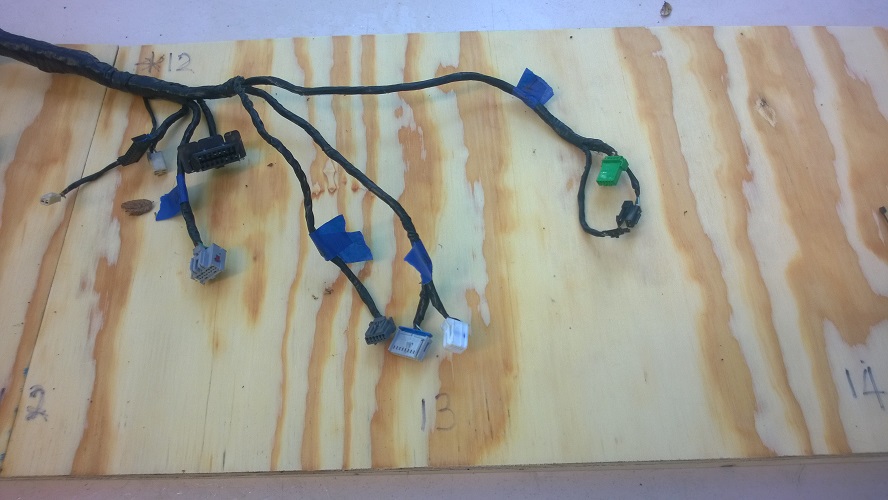

I printed out the thinning guide for the main harness. I then took the lender harness off the table and put my harness on the table tying it loosely starting from the engine end with the initial 8' of the table having connectors in about the proper final position. Then I started thinning. Some of the connectors (and cable that nned to be removed are a bit hard to identify from the pictures in the assembly guide. I will get closeup pictures of each removed connector for Adam to put in the guide.

This evening - in about 4.5 hours I screwed the table together, attached the ties and the pictures and nearly finished the thinning process. I just need to get the tail end wires removed (tail lights, trunk light, rear window defroster). I was surprised how quickly it went. I left about 4" on a saved connector when I cut a removal wired. I will go back and trim them or remove them from the connector. I could not get a final picture tonight as it got dark.

I printed out the thinning guide for the main harness. I then took the lender harness off the table and put my harness on the table tying it loosely starting from the engine end with the initial 8' of the table having connectors in about the proper final position. Then I started thinning. Some of the connectors (and cable that nned to be removed are a bit hard to identify from the pictures in the assembly guide. I will get closeup pictures of each removed connector for Adam to put in the guide.

This evening - in about 4.5 hours I screwed the table together, attached the ties and the pictures and nearly finished the thinning process. I just need to get the tail end wires removed (tail lights, trunk light, rear window defroster). I was surprised how quickly it went. I left about 4" on a saved connector when I cut a removal wired. I will go back and trim them or remove them from the connector. I could not get a final picture tonight as it got dark.