LaunchPad

Well-Known Member

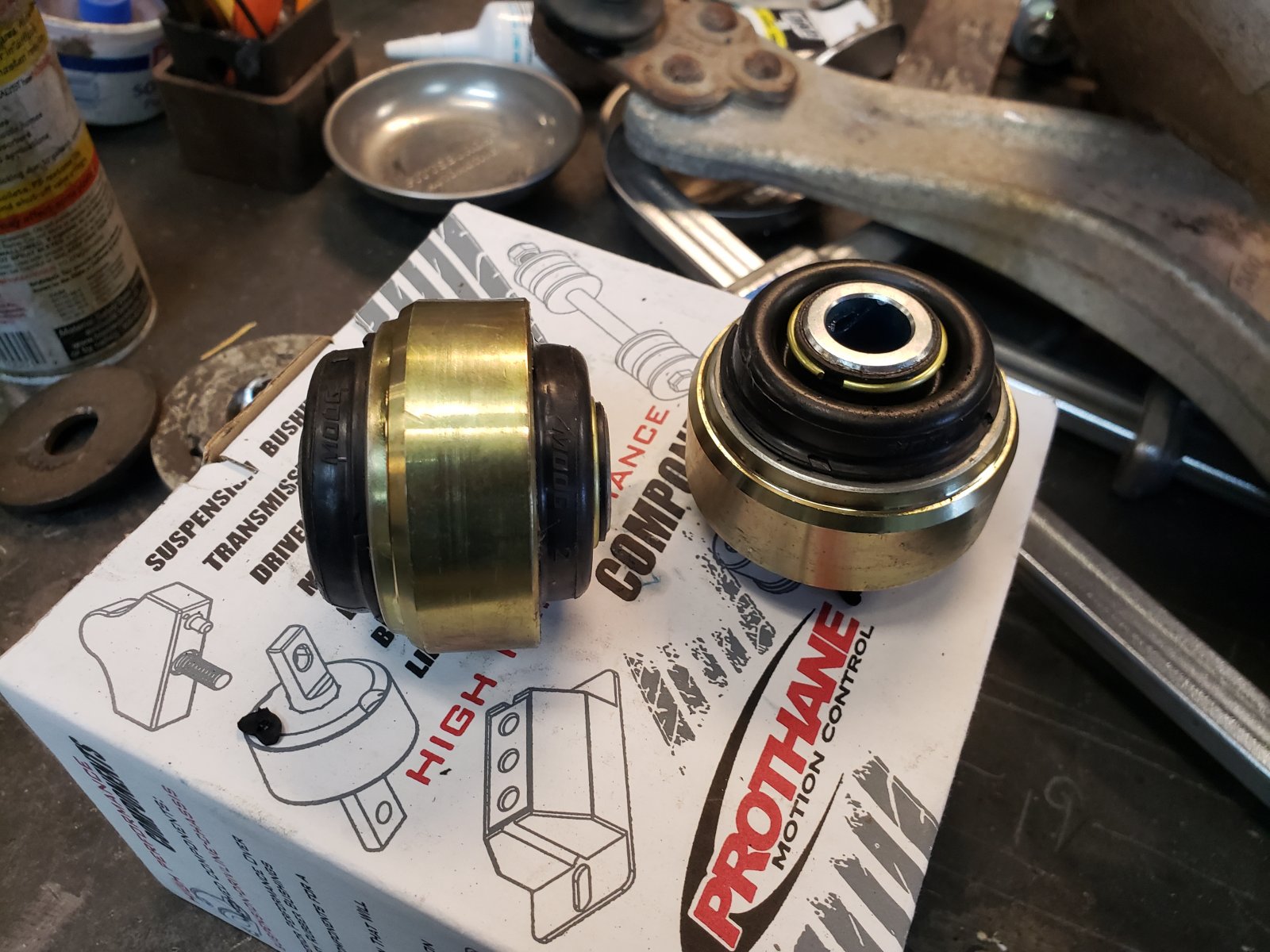

Well my temporary fix is in. the MOOG K201285 bushings showed up. i noticed they are tapered on one side and offset 1/4inch from being centered. So which goes up as the arms are fit in the car?

it will be a bit of a shame to paint these old beat-up arms i cleaned up. While not a mirror finish like another set i saw on the forum. . . i do like the wire brush effect! Especially so compared to the state they were in beforehand.

it will be a bit of a shame to paint these old beat-up arms i cleaned up. While not a mirror finish like another set i saw on the forum. . . i do like the wire brush effect! Especially so compared to the state they were in beforehand.